INDIA'S LEADING MANUFACTURER OF PRECISION COMPONENTS

Specializing in metal and plastic manufacturing with advanced CNC capabilities, press components, and comprehensive fabrication services.

INDIA'S LEADING MANUFACTURER OF PRECISION COMPONENTS

Specializing in metal and plastic manufacturing with advanced CNC capabilities, press components, and comprehensive fabrication services.

Engineered to Perform, Built to Last

PM Tools & Components is a professionally managed precision manufacturing company delivering metal and plastic components with tight tolerances and consistent quality.

With advanced machinery, an experienced technical team, and strict quality systems, we support OEMs with:

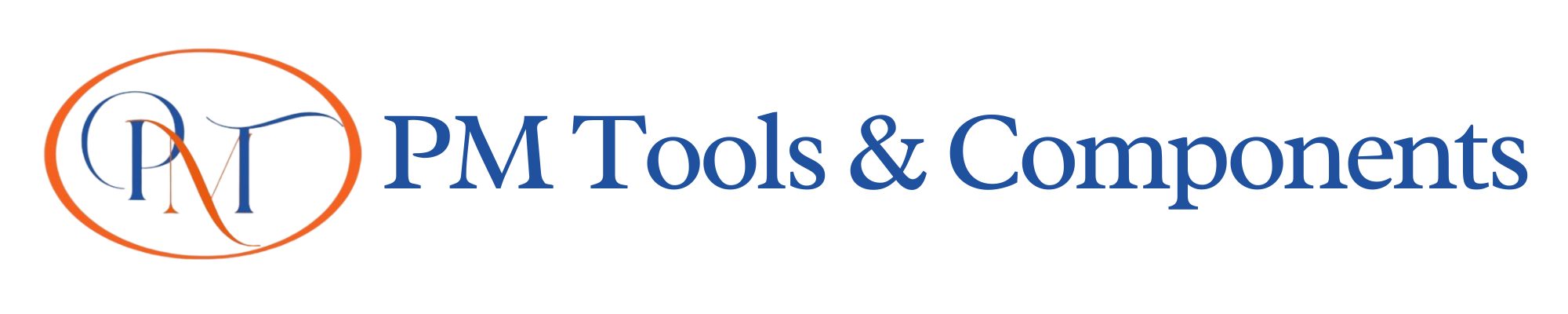

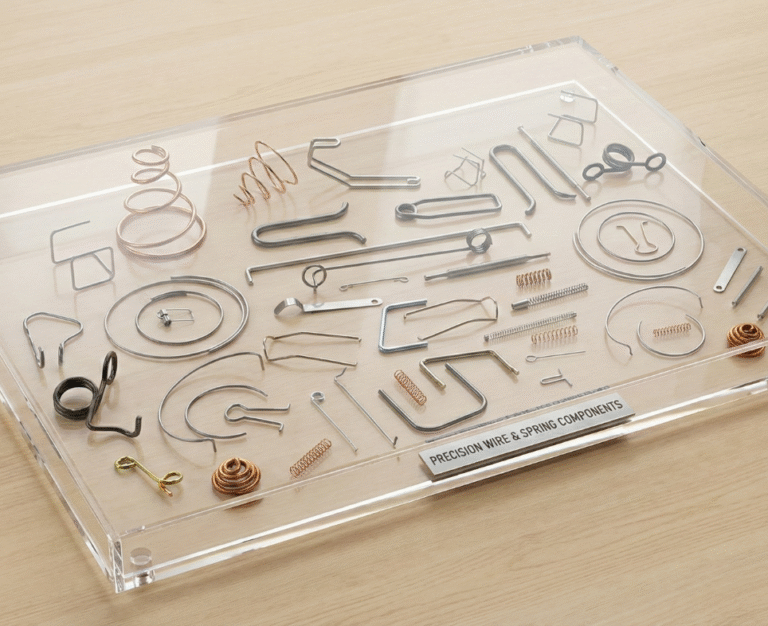

- Precision Springs & Wire Forms

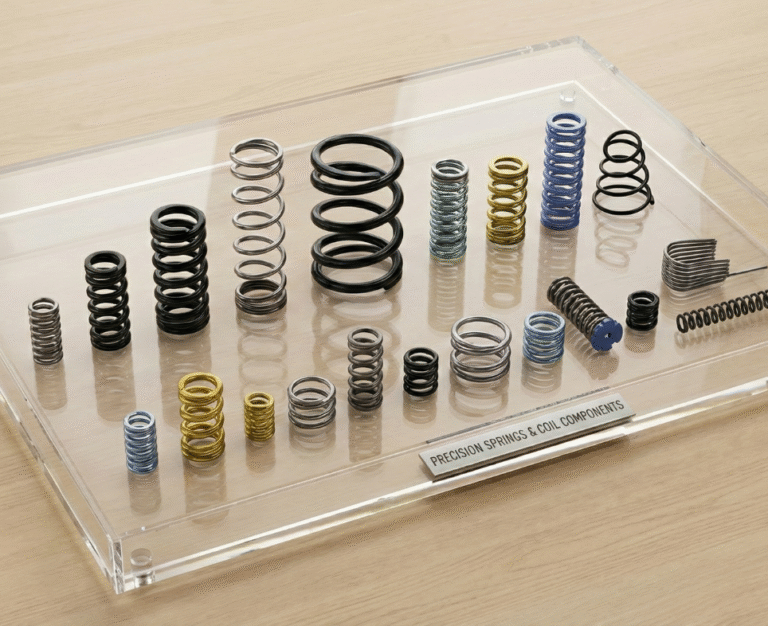

- Sheet Metal & Stamping Components

- High-volume & repeat production

- Custom prototypes to mass production

Our Core Expertise

Precision manufacturing delivered through advanced technology, expert craftsmanship, and strict quality control.

Why Choose PM Tools & Components

Decades of expertise, modern technology, and unwavering commitment to quality.

Advanced

Manufacturing

Smart

Design

Fast

Prototyping

Quality

Certified

Industries We Serve

Our precision components are trusted across multiple industries, from automotive and aerospace to consumer electronics and industrial equipment. With decades of experience and ISO-certified quality systems, we deliver components that meet the demanding requirements of modern manufacturing.

E-Mobility

Rail

Aerospace

Consumer Electronics

Office Automation

Agriculture

Toys

Automotive

Pharmaceutical Devices

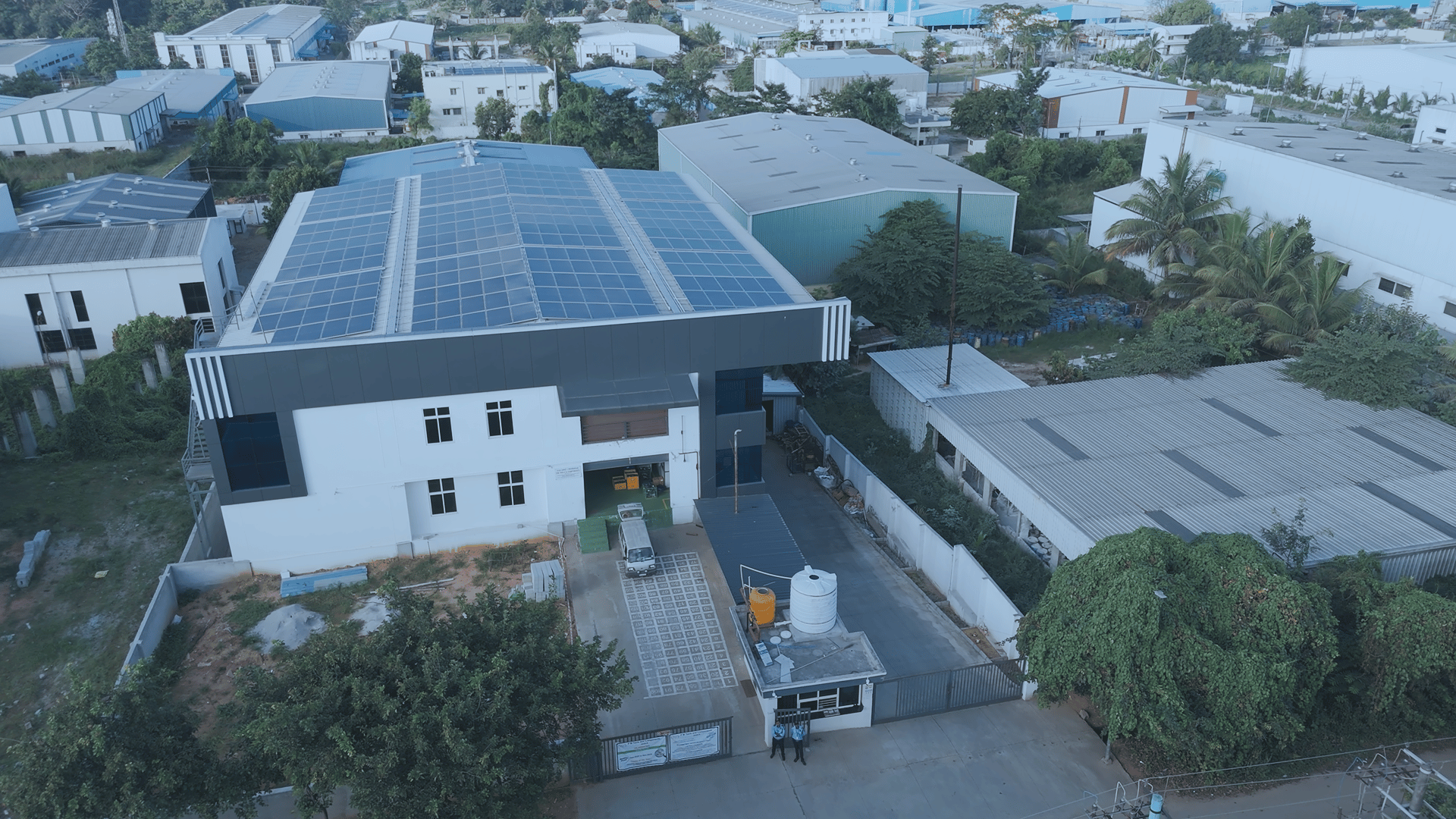

Unit 1

Dedicated facility for precision welding, in-house tooling, perforation, and all secondary manufacturing operations.

- MIG welding

- Tig welding

- Spot welding

- Tool room machines

- Perforation machines

Unit2

Primary production facility equipped for large-scale press manufacturing, wire forming, and precision assemblies.

- Wire forming machine

- Press machines from 35 ton to 250 tons

- Spring forming machine

- Multi forming machine

- Tube bending machine

Trusted by 25,000+ world-class brands and organizations of all sizes.